3D Printing

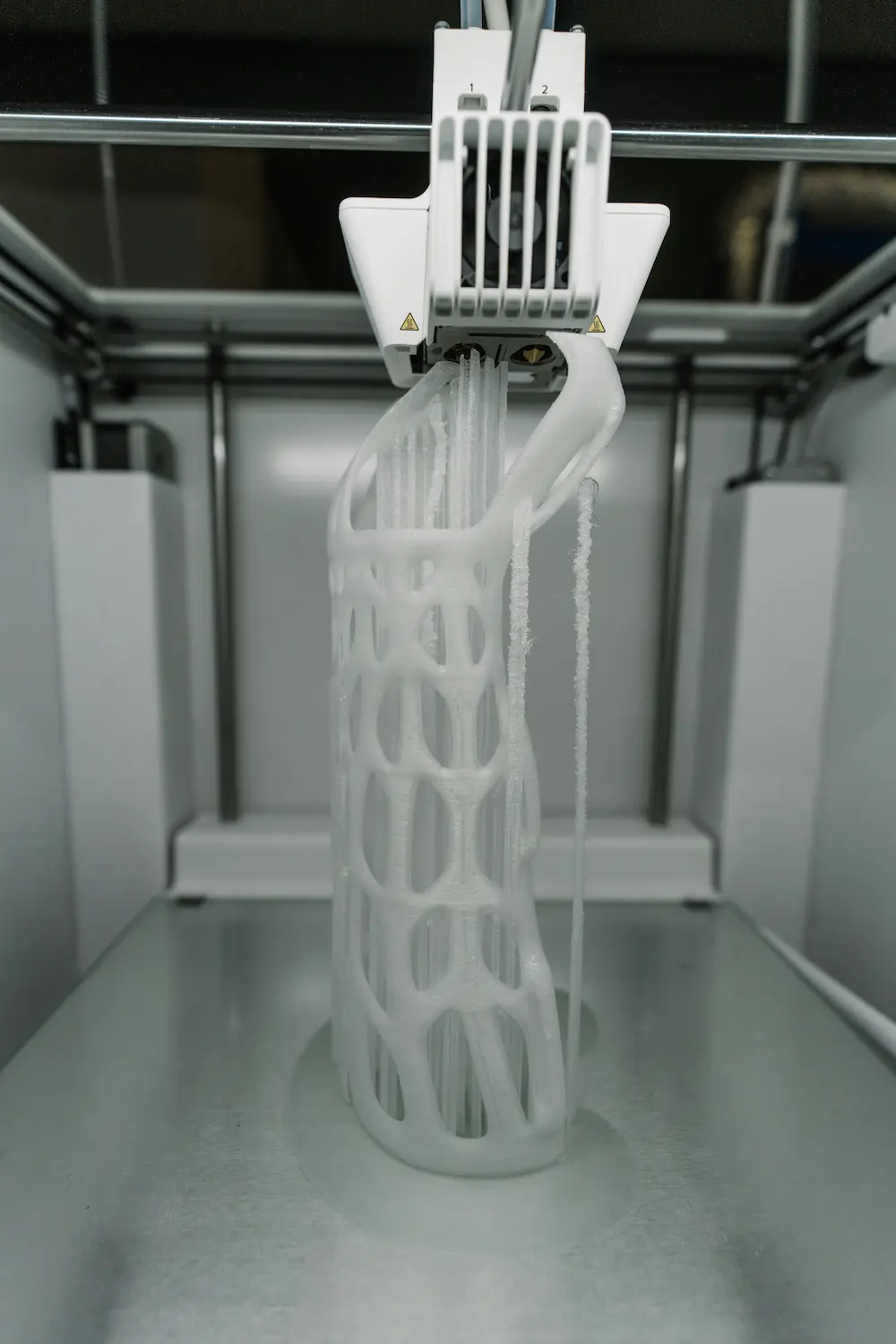

Advanced additive manufacturing for prototypes and functional parts with complex geometries

Request a QuoteWhat is 3D Printing?

3D printing is an additive manufacturing process that builds parts layer by layer, allowing the creation of complex geometries without the need for additional tools. It is ideal for prototypes, custom parts, and low-volume production, offering flexibility and speed.

3D Printing Capabilities

FDM (Fused Deposition Modeling)

A technique that uses thermoplastic filament extrusion, perfect for creating functional prototypes and large parts with high precision.

SLA (Stereolithography)

Uses laser-cured photosensitive resin to achieve high-precision parts, exceptional details, and smooth surfaces, ideal for demanding applications.

SLS (Selective Laser Sintering)

Uses a laser to compact and harden polymer powder, allowing the manufacture of resistant parts without the need for additional supports.

DMLS (Direct Metal Laser Sintering)

3D printing in metal by sintering metal powders with laser, offering high-strength and precision parts.

3D Printing Materials

| Material | Characteristics | Applications |

|---|---|---|

Standard Resin |

| Ideal for creating prototypes and parts with precise details. |

Stainless Steel 316L |

| Used in medical, aerospace, and other applications requiring high corrosion resistance. |

Titanium Ti6Al4V |

| Used in the medical industry (implants) and aerospace due to its strength and biocompatibility. |

PLA |

| Used in prototypes, models, and educational projects. |

ABS |

| Used in mechanical parts, functional prototypes, and consumer products. |

PETG |

| Ideal for containers, protective covers, and applications requiring transparency. |

Ready to Start Your Project?

Get in touch with our team to discuss your manufacturing needs and receive a custom quote.